Address: No.1118 Lanzhou Road, Luxi New Area, Heze City, Shandong Province Sales

Hotline: 400-0059-318

Telephone: 86-0530-5558318

E-mail: hezsam318@outlook.com

hotline:400-0059-318

hotline:400-0059-318

hotline

400-0059-318Address: No.1118 Lanzhou Road, Luxi New Area, Heze City, Shandong Province Sales

Hotline: 400-0059-318

Telephone: 86-0530-5558318

E-mail: hezsam318@outlook.com

Website: www.hzsam.cc

ContactPrinciple

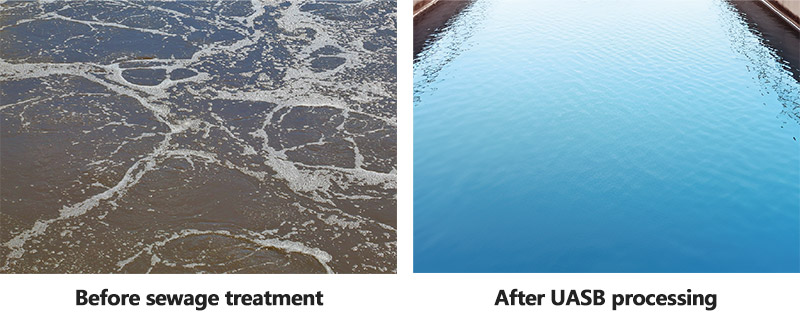

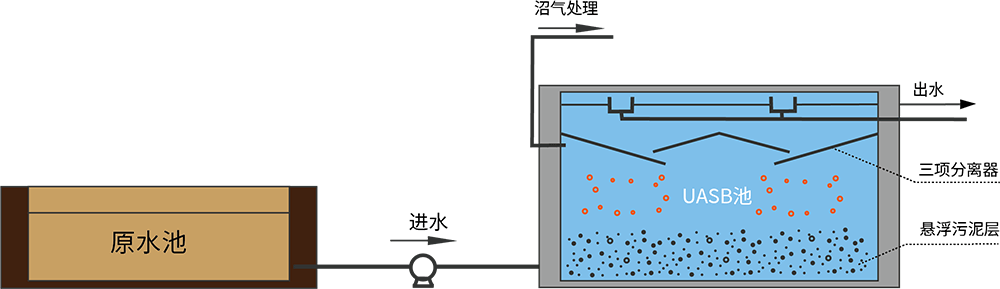

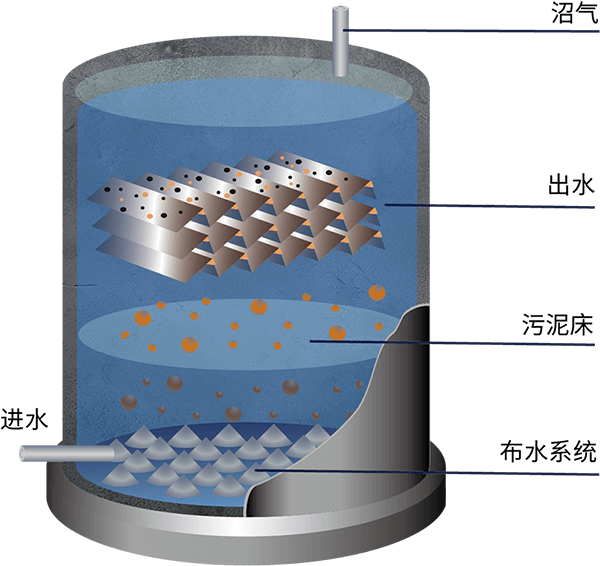

The upper part of the UASB reactor is equipped with a three-phase separator for gas, solid, and liquid. The lower part consists of a sludge suspension layer area and a sludge bed area. Wastewater is uniformly pumped into the sludge bed area from the bottom of the reactor and reacts fully with anaerobic sludge. The organic matter is decomposed into biogas by anaerobic microorganisms. Liquid, gas, and solid form a mixed liquid flow that rises to the three-phase separator, effectively separating the three and converting over 80% of the organic matter into biogas, completing the wastewater treatment process. Its advantages are mainly reflected in the formation of granular sludge, which significantly increases the sludge concentration in the reactor, greatly shortens the hydraulic retention time, and thus improves operational efficiency.

Working principle

UASB consists of three parts: sludge reaction zone, gas-liquid solid three-phase separator (including sedimentation zone), and gas chamber. There is a large amount of anaerobic sludge left in the bottom reaction zone, and sludge with good sedimentation and coagulation properties forms a sludge layer in the lower part. The sewage to be treated flows from the bottom of the anaerobic sludge bed and mixes with the sludge in the sludge layer. The microorganisms in the sludge decompose the organic matter in the sewage and convert it into biogas.

At the upper part of the sludge bed, a sludge with a relatively thin concentration is formed due to the stirring of biogas, which rises together with water and enters the three-phase separator. Then, it passes through the water layer and enters the gas chamber, where the biogas is concentrated and exported through a conduit.

The solid-liquid mixture is reflected and enters the sedimentation zone of the three-phase separator. The sludge in the sewage undergoes flocculation, and the particles gradually increase and settle under gravity. Settle into the anaerobic reaction zone to accumulate a large amount of sludge. After separation from the sludge, the treated effluent overflows from the upper part of the overflow weir in the sedimentation zone and is then discharged from the sludge bed.

Technical advantages

High processing efficiency

The UASB anaerobic reactor has a high organic matter removal rate and biogas yield, making it suitable for treating high concentration organic wastewater.

Energy saving and environmental protection

Due to the lack of aeration during anaerobic fermentation, the operating energy consumption is relatively low.

Easy to operate

The UASB anaerobic reactor has a simple structure, convenient operation, and is easy to maintain and manage.

Good stability

This reactor has high resistance to impact loads and can adapt to changes in water quality and quantity.

Small footprint

Efficient anaerobic fermentation technology is adopted, and the reactor occupies a small area.

High volumetric load rate

Improve capacity utilization and avoid blockage issues.

Applications

High concentration organic wastewater: such as wastewater containing alcohol, molasses, citric acid, etc.

Medium concentration wastewater: such as wastewater from beer slaughtering, breeding, soft drinks, etc.

Low concentration wastewater: such as domestic sewage and other wastewater.