Address: No.1118 Lanzhou Road, Luxi New Area, Heze City, Shandong Province Sales

Hotline: 400-0059-318

Telephone: 86-0530-5558318

E-mail: hezsam318@outlook.com

location:

home

-

Intelligent aerobic fermentation equipment for organic solid waste of livestock and poultry

location:

home

-

Intelligent aerobic fermentation equipment for organic solid waste of livestock and poultry

hotline:400-0059-318

hotline:400-0059-318

hotline

400-0059-318Address: No.1118 Lanzhou Road, Luxi New Area, Heze City, Shandong Province Sales

Hotline: 400-0059-318

Telephone: 86-0530-5558318

E-mail: hezsam318@outlook.com

Website: www.hzsam.cc

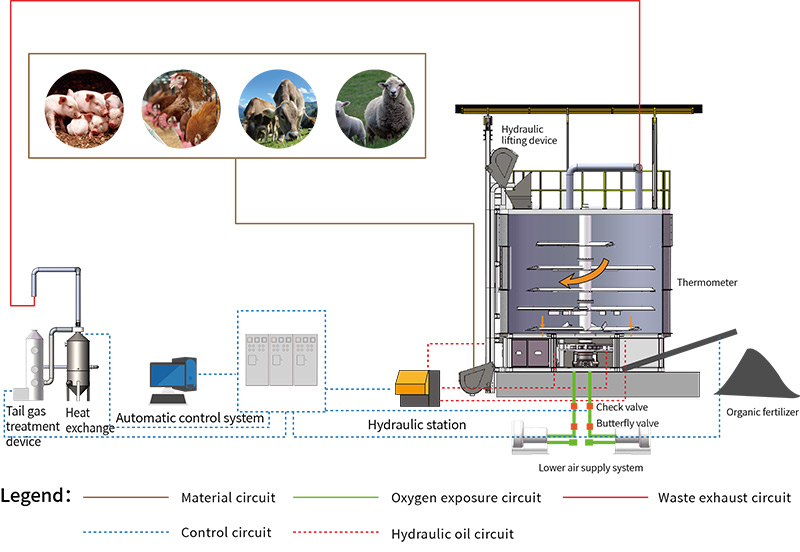

ContactEquipment introduction

The whole equipment structure is divided into four parts. The lower base is distributed with hydraulic station, vortex air pump, hydraulic cylinder, heating system and ratchet drive system, etc. The inner wall of the tank is lined with 304 stainless steel plate, which can effectively extend the life of the tank and reduce the residue of decomposed materials. The insulation layer is filled with polyurethane in the middle, and the outer wall is composed of thickened carbon steel plate or 201 stainless steel; the upper part is composed of a weather shed, a testing platform and exhaust facilities. The auxiliary equipment includes hydraulic loading and lifting device, exhaust gas filtration and deodorization system, heat exchange system device, automatic control system and discharging system.

Process flow chart of intelligent aerobic fermentation of organic solid waste of livestock and poultry

The organic waste of livestock and poultry is added to the high temperature aerobic fermenter. The whirlpool air pump at the bottom of the fermenter delivers oxygen through the aeration hole on the stirring shaft. At the same time, the stirring shaft is stirred. Under the action of the biological starter, the temperature gradually rises to 50-70℃. The material in the fermentation room falls layer by layer under the action of the spindle and gravity, and the fermented organic fertilizer is discharged from the discharge port.

Area of application

Organic fertilizer fermenter is suitable for treating all kinds of organic wastes and producing high-efficiency organic fertilizer.

It can treat chicken manure, pig manure, cattle and sheep manure, rabbit manure, and other livestock manure.

It can handle the carcasses of chickens, cattle, sheep, horses, rabbits, pigs and other livestock and poultry.

It can handle all kinds of organic kitchen waste.

It can treat industrial wastes such as distiller's grains, vinegar distiller's grains, mucao dregs, sugar dregs and furfural dregs.

It can treat urban sludge such as river silt and sewer silt.

It can treat crop wastes such as straw, soybean meal and so on.

Equipment parameter

Intelligent aerobic fermentation equipment 130 square technical parameters

Intelligent aerobic fermentation equipment 200 square technical parameters

Project | parameters |

Blower | 22kw |

Hydraulic Power Station | 15kw |

Hopper hoist | 3.75KW |

Exhaust blower | 5.5kw |

Tail gas circulating water pump | 0.75kw |

Discharge conveyor belt | 4.5kw |

Total installed power | 51.2KW |

Floor space | 100㎡ |

Whole fermentation chamber | Diameter of 7.8m, 9.5m high, volume of 200m³ |

Main engine weight | 55 tons |

Loading mode | Hydraulic loading |

Deodorizing method | Integrated deodorization system |

Lubriation method | Integrated automatic lubrication |

Daily electricity consumption | Low frequency power consumption around 610kw/h High frequency power consumption of about 840kw/h |

Daily treatment capacity (Waste water content 70-75% ) | Low frequency operation 25.5 kw, processing 16 tons per day High frequency operation 35 kw, processing 22 tons a day |

The size can be customized for different situations

The utility model relates to a transmission device of aerobic fermentation equipment for livestock and poultry manure

The utility model relates to a transmission device of aerobic fermentation equipment for livestock and poultry manure The utility model relates to a fermentation and drying device for livestock and poultry manure recycling organic fertilizer

The utility model relates to a fermentation and drying device for livestock and poultry manure recycling organic fertilizer The utility model relates to a stirring device for a fecal aerobic fermentation equipment

The utility model relates to a stirring device for a fecal aerobic fermentation equipment The utility model relates to a sealing device for a fecal aerobic fermentation equipment

The utility model relates to a sealing device for a fecal aerobic fermentation equipment Utility model The utility model relates to a vertical aerobic compost fermentation device

Utility model The utility model relates to a vertical aerobic compost fermentation device Utility model relates to an automatic feeding and discharging device

Utility model relates to an automatic feeding and discharging device The utility model relates to a fermentation equipment for livestock and poultry manure recycling organic fertilizer

The utility model relates to a fermentation equipment for livestock and poultry manure recycling organic fertilizer The utility model relates to a heating device for fermentation equipment of livestock and poultry manure recycling organic fertilizer

The utility model relates to a heating device for fermentation equipment of livestock and poultry manure recycling organic fertilizer The utility model relates to a fermentation device for livestock and poultry manure recycling organic fertilizer

The utility model relates to a fermentation device for livestock and poultry manure recycling organic fertilizer Utility model The utility model relates to a drying equipment for livestock and poultry manure recycling organic fertilizer

Utility model The utility model relates to a drying equipment for livestock and poultry manure recycling organic fertilizer